FACI GAS is a highly efficient hot water boilers with a capacity from 500 to 3500 kW, created specifically to provide heat to any of your facilities.

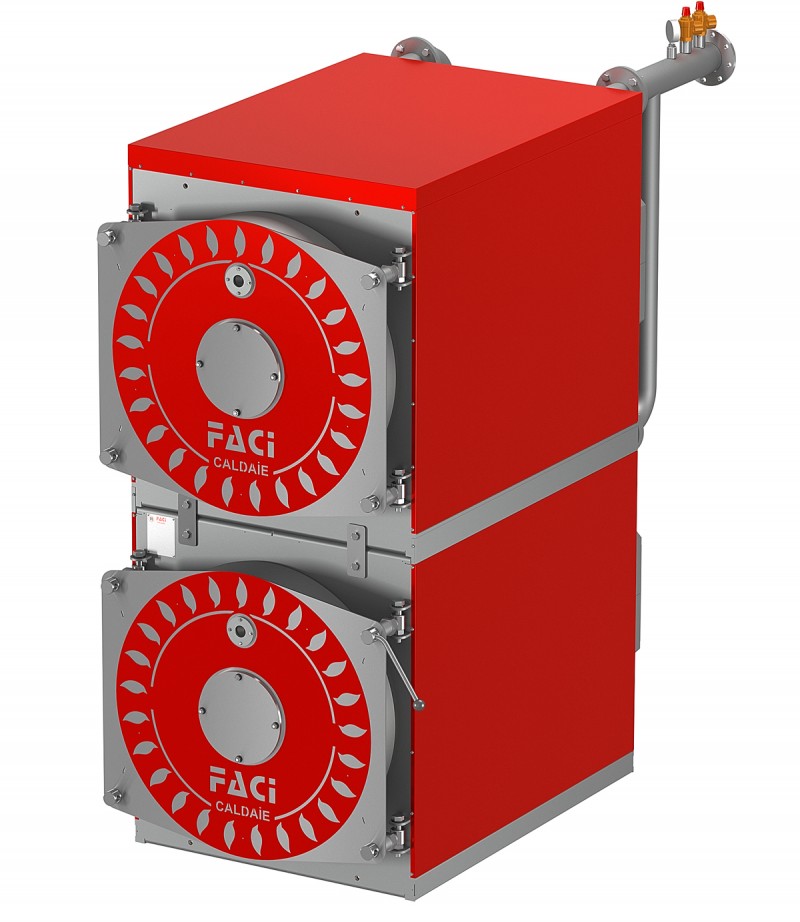

FACI GAS can be installed on top of each other, which allows you to get additional free space in the room.

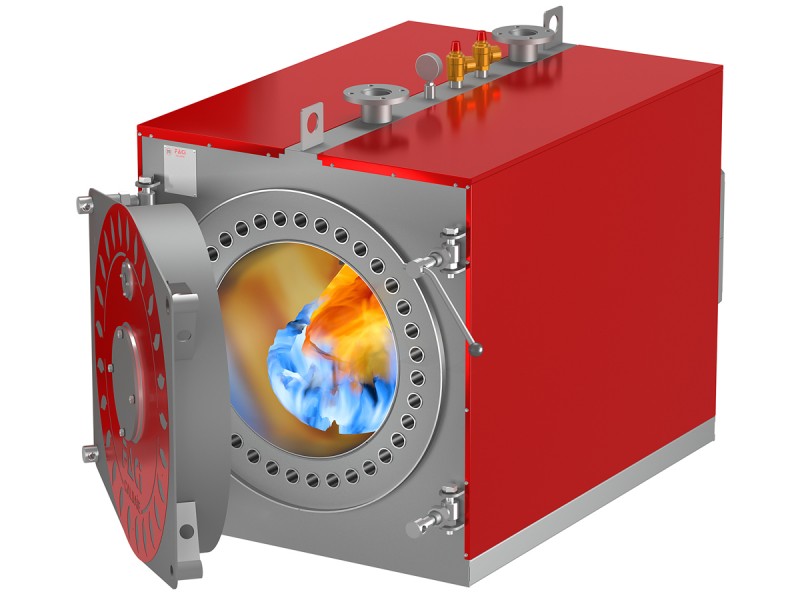

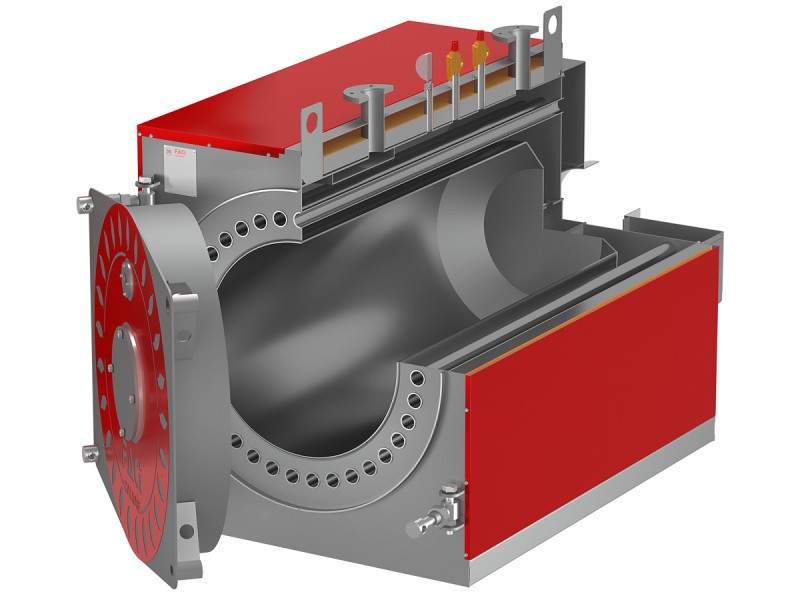

The FACI GAS furnace chamber has an inversion cylindrical shape with a radial arrangement of smoke pipes. Special hot air swirlers - turbulators are installed in the pipes.

All these features contribute to the maximum transfer of hot air temperature to the coolant, provide efficiency up to 95%, and also save fuel.

The connections to the supply and return lines, as well as the connections for the installation of instrumentation and safety valves are arranged in such a way as to ensure easy and fast connection to the system.

The body of the FACI GAS boiler has a special design to ensure uniform distribution of the coolant throughout the water jacket. In this way, a dangerous temperature difference of the coolant inside the boiler is prevented.

Double installation of boilers is possible both vertically and horizontally

Double installation of boilers is possible both vertically and horizontally Professional level welding quality

Professional level welding quality Evenly distributed coolant throughout the water jacket

Evenly distributed coolant throughout the water jacket Convenient connection and fast service

Convenient connection and fast service Special turbulators are already included

Special turbulators are already included Special heat-resistant lining of doors and thermal insulation of the high-density housing

Special heat-resistant lining of doors and thermal insulation of the high-density housing Efficiency up to 95%

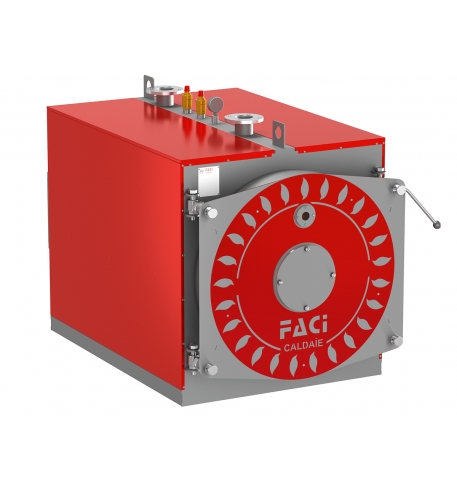

Efficiency up to 95% Reversible doors

Reversible doors