Description:

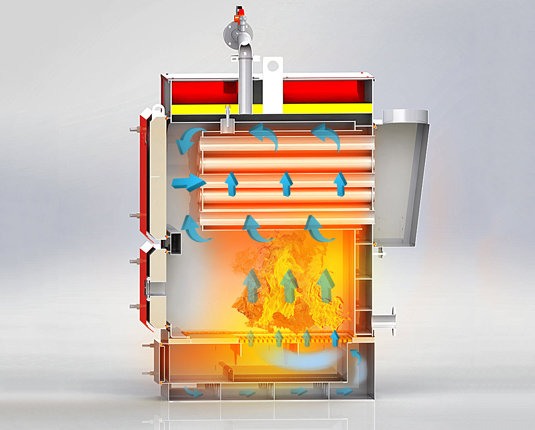

Optimal air flow

The movement of the air flow in the Faci solid fuel boiler is realized according to a unique technology that makes it possible to achieve an optimal air flow in the boiler without the use of automatics.

The air mixture enters the boiler through an adjustable damper on the right or left side.

Huge stoking chamber

Next, the air mixture passes through the air box through the perforated bulkheads, travels along the rear wall of the boiler and exits through the openings in the ash drawer.

The huge stoking chamber is an important advantage of FACI TT boilers.

Look at the dimensions of the boiler and compare with the dimensions of boilers of similar capacity that are offered to you - and immediately it becomes clear where the honest long-lasting combustion is.

Really long combustion and removable grates

The air then passes through the grate and keeps the fuel burning in the very epicenter of the boiler - under the heat exchanger.

This makes it possible to achieve an effective and really long combustion.

In FACI TT we use removable grates. We do not make the grates part of the heat exchanger (water filled), because if they burn, what do you do? Change the boiler? We only suggest changing the grates.

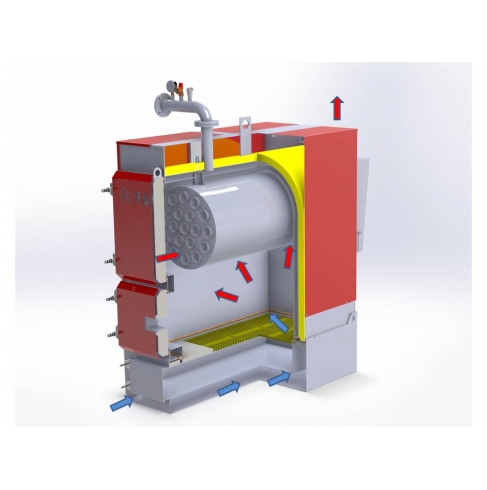

Horizontal heat exchanger

Traditional for FACI boilers drum heat exchanger.

Horizontal heat exchangers are the hallmark of FACI boilers. The boilers are designed so that the flue gases from the burned fuel passes many times around a cylindrical heat exchanger.

This allows the maximum heat removal from the flue gases and achieve high efficiency.

And by installing turbulators you can increase the efficiency by another 5-7%!

Maximum long-term combustion

Maximum long-term combustion Removable grates

Removable grates Convenient niche for ash removal

Convenient niche for ash removal Maximum heat transfer - high efficiency

Maximum heat transfer - high efficiency